In the intricate tapestry of industrial equipment, the microchannel heat exchanger has emerged as a cutting-edge solution, transforming the landscape of thermal management. This advanced technology represents a paradigm shift in the way industries handle heat exchange processes, offering a host of benefits that enhance efficiency and performance. In this article, we will delve into the world of microchannel heat exchangers, exploring their key features, applications, and the significant impact they have on various industrial sectors.

Understanding Microchannel Heat Exchangers

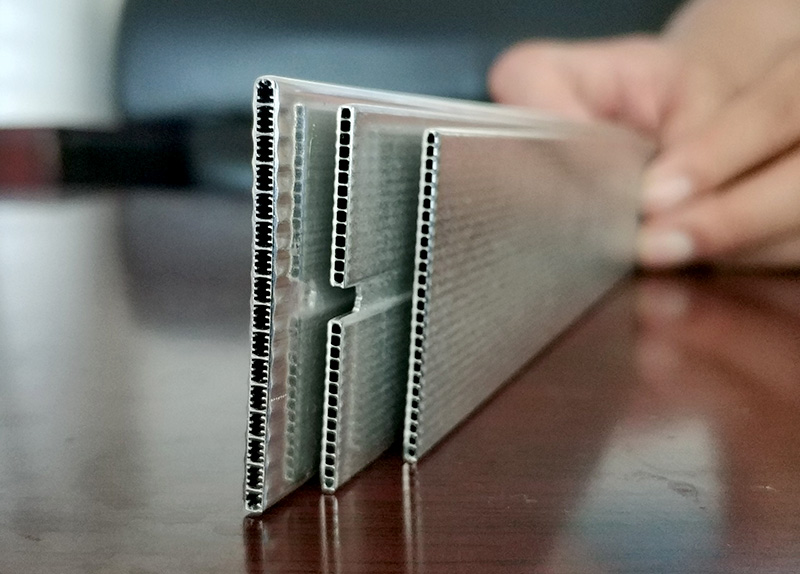

At its core, a microchannel heat exchanger is a specialized device designed to facilitate the transfer of thermal energy between two fluid streams. What sets it apart is its intricate design, featuring a network of small channels, typically on the micrometer scale. These microchannels serve as conduits for the exchange of thermal energy, providing a more efficient and compact alternative to traditional heat exchangers.

Key Features and Advantages

Compact Design: The hallmark of microchannel heat exchangers is their compact and space-efficient design. The microscale channels allow for a higher surface area-to-volume ratio, enabling the creation of smaller and lighter heat exchangers without compromising their thermal efficiency. This feature is particularly beneficial in industries where space optimization is critical.

- Enhanced Heat Transfer Efficiency: The small dimensions of the channels promote turbulent flow, leading to a more effective convective heat transfer between the fluid streams. This heightened efficiency is a significant advantage in applications where precise temperature control and rapid heat exchange are essential.

- Reduced Material Usage: The compact nature of microchannel heat exchangers not only contributes to space efficiency but also results in a reduction in material usage. This has economic and environmental implications, as it helps minimize the raw materials required for manufacturing, aligning with sustainable practices.

- Improved Thermal Performance: Microchannel heat exchangers excel in managing high heat fluxes and temperature differentials. Their ability to handle extreme thermal conditions makes them suitable for demanding industrial processes, including those encountered in the aerospace, automotive, and electronics industries.

Applications in Various Industries

Microchannel heat exchangers find applications across a diverse range of industries, showcasing their versatility and efficiency. Some notable applications include:

- Automotive Cooling Systems: Microchannel heat exchangers play a crucial role in automotive cooling systems, efficiently dissipating heat generated by engines and electric vehicle batteries. Their compact size is particularly advantageous in modern vehicle designs, contributing to improved overall performance.

- Electronics Cooling: In the electronics industry, managing heat is crucial for the optimal performance of electronic components. Microchannel heat exchangers play a pivotal role in preventing overheating, ensuring the reliability and longevity of electronic devices.

- HVAC Systems: Microchannel heat exchangers contribute to the efficiency of heating, ventilation, and air conditioning (HVAC) systems. Their compact design and enhanced heat transfer capabilities lead to energy savings and improved overall performance in both residential and commercial settings.

- Renewable Energy Systems: Microchannel heat exchangers are vital components in various renewable energy applications, including solar thermal and geothermal systems. Their efficiency in transferring heat is essential for harnessing and utilizing sustainable energy sources.

Challenges and Considerations

While microchannel heat exchangers offer numerous advantages, they are not without challenges. Issues such as fouling, pressure drop, and manufacturing complexity can be considerations in certain applications. However, ongoing research and advancements in materials and design are addressing these challenges, making microchannel heat exchangers increasingly viable for a broader range of industrial processes.

Conclusion

In conclusion, microchannel heat exchangers represent a significant leap forward in industrial thermal management. With their compact design, enhanced heat transfer efficiency, and diverse applications across industries, microchannel heat exchangers are reshaping the way we approach heat exchange processes. As industries continue to seek more efficient and sustainable solutions, the adoption of microchannel heat exchangers is expected to grow, ushering in a new era of thermal management in the industrial landscape.