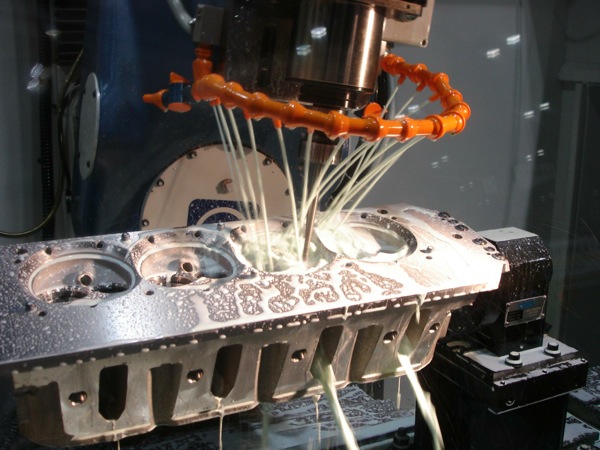

Carbide cutting tools are unmatched for precision machining due to their extreme hardness and heat resistance. These are made from tools such as tungsten powder heated with carbon, surpassing steel in durability. As a result, they deliver cleaner cuts for meticulous woodworking tasks while retaining sharpness longer than conventional blades, offering both efficiency and cost savings.

Another standout quality that sets carbide blades apart from others on the market is their ability to withstand intense temperatures during rapid drilling or cutting operations.

Enhanced Durability and Strength

Carbide-cutting tools stand out because they’re incredibly tough. The secret to their strength is tungsten carbide, a material almost as hard as diamond.

To make it, you heat tungsten powder with carbon until it fuses into a sturdy compound. You can shape this stuff into solid blades or add bits of metal for different uses. What’s great about these powerful carbide blades is that they stay sharp way longer than typical steel ones, meaning less time and cash spent on getting new ones all the time!

Plus, in woodworking, where things get hot fast, these guys keep cool thanks to their ability to handle high temperatures without losing an edge. You have options, whether chopping through tough wood or doing detailed carvings; their heavy-duty nature makes them perfect for every job in your shop. If quality counts, not just any blade will do.

Precision matters when crafting something special from wood. Extra care ensures each cut is clean and exact—a mark of professional workmanship echoed by Suncoast Precision Tools’ commitment to top-notch materials and careful engineering.

Exceptional Heat Resistance

Carbide-cutting tools can withstand intense heat. This is key in tough jobs like high-speed machining or cutting hard materials. When these tools work, they get very hot due to friction against the cut material.

Yet, thanks to tungsten carbide’s properties, high melting point, and excellent thermal management, the tool stays cool enough for consistent performance over long periods. It doesn’t warp or wear down easily under this stress because its solid structure quickly moves heat away from critical areas. Simply put, you can count on your cuts staying sharper longer without the tool giving out on you.

Precision Cutting Performance

Carving intricate designs into wood demands tools that respond accurately to your touch. Solid Carbide Tooling excels here; its sharpness allows for detailed work effortlessly.

This same accuracy ensures clean lines whenever grooving or slotting. These tools are indispensable for tasks like edge profiling and trimming, where a smooth finish is critical due to their precise cuts that minimize extra finishing steps later on. Veneer and laminate cuttings, too, benefit from such precision—no chipping means less waste and rework.

Select the right solid carbide tool for your job to maintain high performance. Monitor wear and follow advised feed rates and spindle speeds closely during operations. Remember: premium quality equipment paired with proper care will reward you with long-lasting precision in all your woodworking endeavors.

Carbide cutting tools offered by Suncoast Precision Tools stand out for their exceptional durability and precision. These tools maintain sharp edges much longer than traditional materials do. They resist wear from heat and friction on tough jobs, too.

This means your work isn’t only accurate and efficient, with fewer replacements needed over time. For any task requiring meticulous detail or enduring through hard-to-machine materials, carbide end mills are the skilled craftsperson’s choice to ensure quality results that meet rigorous professional standards.