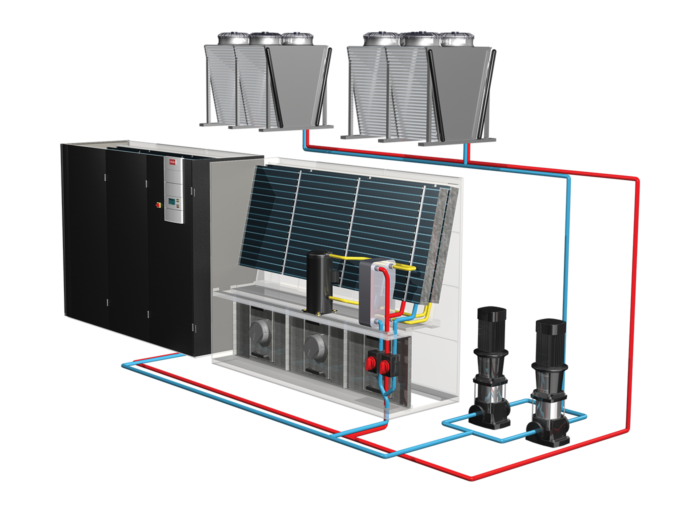

The idea of a free cooling chiller can be applied in different ways in different types of systems. In systems equipped with cooling towers, the condenser is cooled with water. Most often, a shell-and-tube condenser is used for these purposes.

- Cooling steam passing outside the pipes is cooled and condensed by the water circulating inside the pipes.

- At this stage, the water is cooled using cooling towers. This occurs when the chiller is operating in a high ambient temperature environment.

- However, when the ambient temperature drops below the temperature of the water used in the cooling systems, there is no need to operate the equipment of the cooling group.

- In this case, indirect cooling systems, water is directed from the cooling tower, bypassing the free cooling air-cooled chiller, directly to the cooling system.

The main advantage of this system in open circuit cooling towers is that the required cooling water temperature is close to the ambient temperature. In this case, the maximum benefit can be obtained from the use of free cooling technology. However, a serious disadvantage is the contamination of the cold water circuit caused by the relatively dirty condenser water.

Despite attempts to use various technologies for its purification, such as, for example, filtration, the use of these systems has recently become more and more unpopular. This problem can be eliminated by using closed-circuit cooling towers as part of an indirect cooling system or dry coolers (dry coolers).

The use of the direct free-cooling mode ensures a very high energy efficiency of the equipment operation. However, it is important to provide for the following point: the temperature of the air that enters the room directly must be certain. It should also be clean enough. This leads to the need to install additional devices that purify the air.