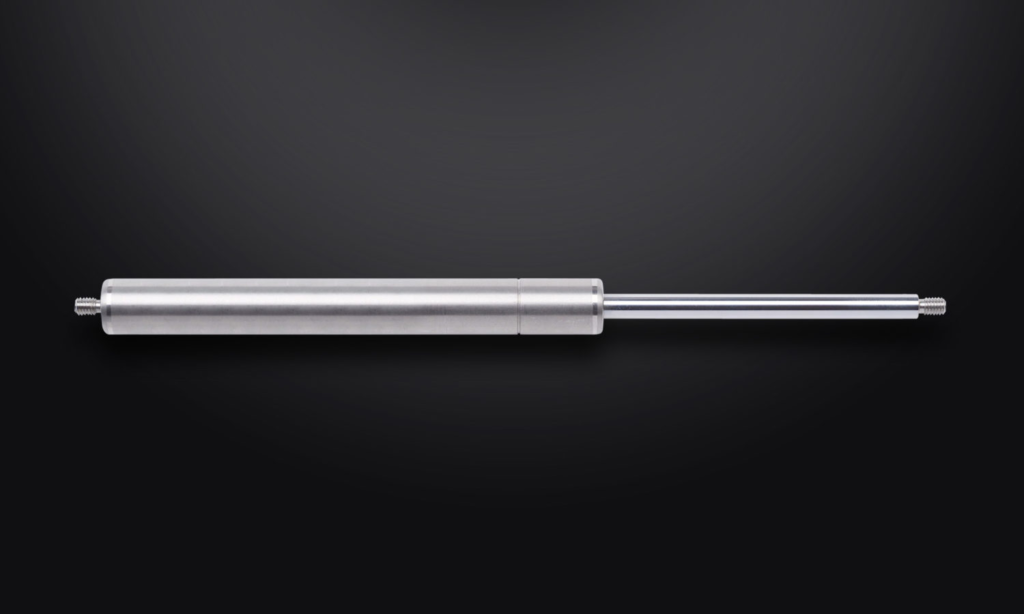

When building a new home, you might be faced with the need to install steel gas-type struts in your concrete foundation. These devices are designed specifically to support load-bearing columns but are also widely used as a structural column tie or suspension cable.

There are many steel gas-type struts on the market, but not all are created equal.

Steel gas-type struts are incredibly durable. They can handle a lot of stress and pressure, which is why steel gas struts are so popular among car manufacturers and other businesses that rely on vehicles for transportation.

Steel struts are lighter than their aluminium counterparts, which makes them easier to move and transport. This is especially important if you have to install the strut in a tight space or if you need to move it around continually.

Benefits of steel gas struts

One of the many widespread benefits of using steel gas struts is that they are solid and last a long time. They are much more affordable than other strut types, making them a good option for larger projects. Additionally, these struts can be customised to meet the specific needs of your project.

Advantages of steel gas-type struts

Steel gas struts are famous for various applications due to their many advantages. Here are some of the most commonly known reasons why this device is a good choice:

-They’re flexible: Steel gas-type struts are adjustable to conform to different shapes and sizes. This makes them perfect for applications that need flexibility or movement.

-They’re easy to install: Steel gas-type struts are easy to install, so you can get them up and running quickly.

Types of steel gas strut applications

Bridge Struts

A bridge strut is typically used to support a considerable weight across a large distance. They are often used in bridges and other large structures. Bridge struts are typically made out of steel tubing or wire mesh. They must be strong enough to support the weight and light adequately and not add excess weight to the bridge itself.

Warehouse Struts

A warehouse strut is typically used to support heavy loads stably. They are perfect for storing goods or holding up ceilings. Warehouse struts are metal tubing or bars with cross-sections similar to a beam or column.

Structural applications

Structural Steel Gas struts have become increasingly popular to support loads in static and dynamic applications.

These struts are made from various materials, including aluminium, carbon fibre, and steel. They come in diverse shapes and sizes and can be used in multiple structural applications. The most common uses for these items are as load-bearing members in static structures such as bridges, buildings, and stadiums or as part of dynamic systems such as suspension bridges and aircraft wings.

There are a few influential things to consider when selecting steel gas strut components. The type of strut you choose will depend on the application. The size and shape of the strut will vary depending on the application. For example, aircraft wings use cantilevers, while stadiums use arching struts.

Conclusion

Steel gas-type struts have been the standard way to mount heavy loads on trucks, trailers, cars, and other vehicles for decades. Many alternative materials and mounting systems are available today, but steel gas struts remain one of the most dependable and affordable ways to mount large loads.